500T Pipe Conventional Welding Roller For Pipe Butt With Bolt Adjustment

✧ Introduction

1.Our pipe welding rotators pack One drive piece roller & one idler piece roller together as one set for sale.

2.Our tank tuning rolls' drive rotation speed is in digital readout.

3.Top-class electronic components from Schneider to ensure long time using life

4.Remote hand control, Radio hand control & Foot pedal control are all avaialble.

5.100% new from original manufacturer

6. If your single pipe length more than 8 meter, we suggest you choose one drive roller and two idler rollers to support.

✧ Main Specification

| Model | CR-500 Welding Roller |

| Turning Capacity | 500 Ton maximum |

| Loading Capacity-Drive | 250 Ton maximum |

| Loading Capacity-Idler | 250 Ton maximum |

| Vessel size | 1200~8500mm |

| Adjust Way | Bolt adjustment |

| Motor Rotation Power | 2*11 KW |

| Rotation Speed | 100-1000mm/min |

| Speed control | Variable frequency driver |

| Roller wheels | Steel Material |

| Roller size |

Ø800*400mm

|

| Voltage | 380V±10% 50Hz 3Phase |

| Control system | Remote control 15m cable |

| Color | Customized |

| Warranty | One year |

| Certification | CE |

✧ Feature

1.The pipe welding rollers product has following different series,say, the self-alignment, the adjustable, the vehicle, the tilting and the anti-drift types.

2.The series conventional pipe welding rollers stand is able to adopt to various diameter of job, by adjust the center distance of rollers, via reserved screw holes or lead screw.

3.Depends on different application, the roller surface has three types,PU/RUBBER/STEEL WHEEL.

4.The pipe welding rollers is mainly used for Pipe Welding ,tank rolls polishing,turning roller painting and tank turning rolls assembly of cylindrical roller shell.

5.The pipe welding turning roller machine can joint control with other equipments.

✧ Spare Parts Brand

1.Variable Frequency Drive is from Danfoss / Schneider brand.

2.Rotation and tilring Motors are Invertek / ABB brand.

3.Electric elements is Schneider brand.

All the spare parts are easily to replace at end user local market.

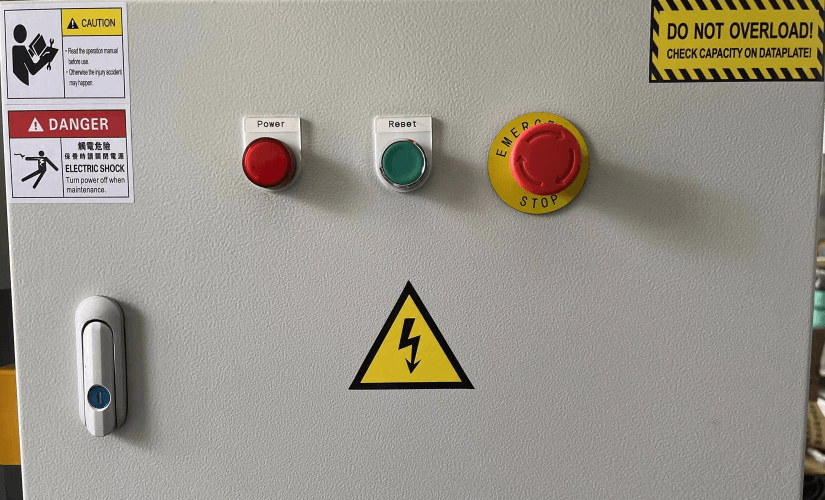

✧ Control System

1.Remote Hand control box with Rotation speed display, Rotation Forward , Rotation Reverse, Tilting Up, Tilting Down, Power Lights and Emergency Stop functions.

2. Main electric cabinet with power switch,Power Lights, Alarm , Reset functions and Emergency Stop functions.

3.Foot pedal to control the rotation direction.

4.We also add one additional Emergency stop button on the machine body side, this will ensure the work can stop the machine at the first time once any accident occur.

5.All our control system with CE approval to European market.

✧ Previous Projects