Hydraulic Lifting Pipe Turning Welding Positioner 2Ton With 3 Jaws Chuck

✧ Introduction

Hydraulic lifting pipe turning welding positioner is a specialized device used in welding operations to position and rotate pipes or cylindrical workpieces for welding. It incorporates hydraulic lifting mechanisms to lift and support the pipe, as well as rotation capabilities for controlled rotation during the welding process.

Here are some key features and characteristics of a hydraulic lifting pipe turning welding positioner:

- Hydraulic Lifting Mechanism: The positioner is equipped with hydraulic cylinders or hydraulic jacks that provide the lifting force to elevate and support the pipe. The hydraulic system allows for precise control and adjustment of the pipe's height.

- Pipe Clamping System: The positioner typically includes a clamping system that securely holds the pipe in place during welding. This ensures stability and prevents movement or slippage during the rotation process.

- Rotation Capability: The positioner allows controlled rotation of the pipe, providing easy access to different welding positions and angles. The rotation speed and direction can be adjusted based on the welding requirements.

- Adjustable Positioning: The positioner often features adjustable features such as tilt, height, and rotation axis alignment. These adjustments enable precise positioning of the pipe, ensuring optimal access for welding on all sides.

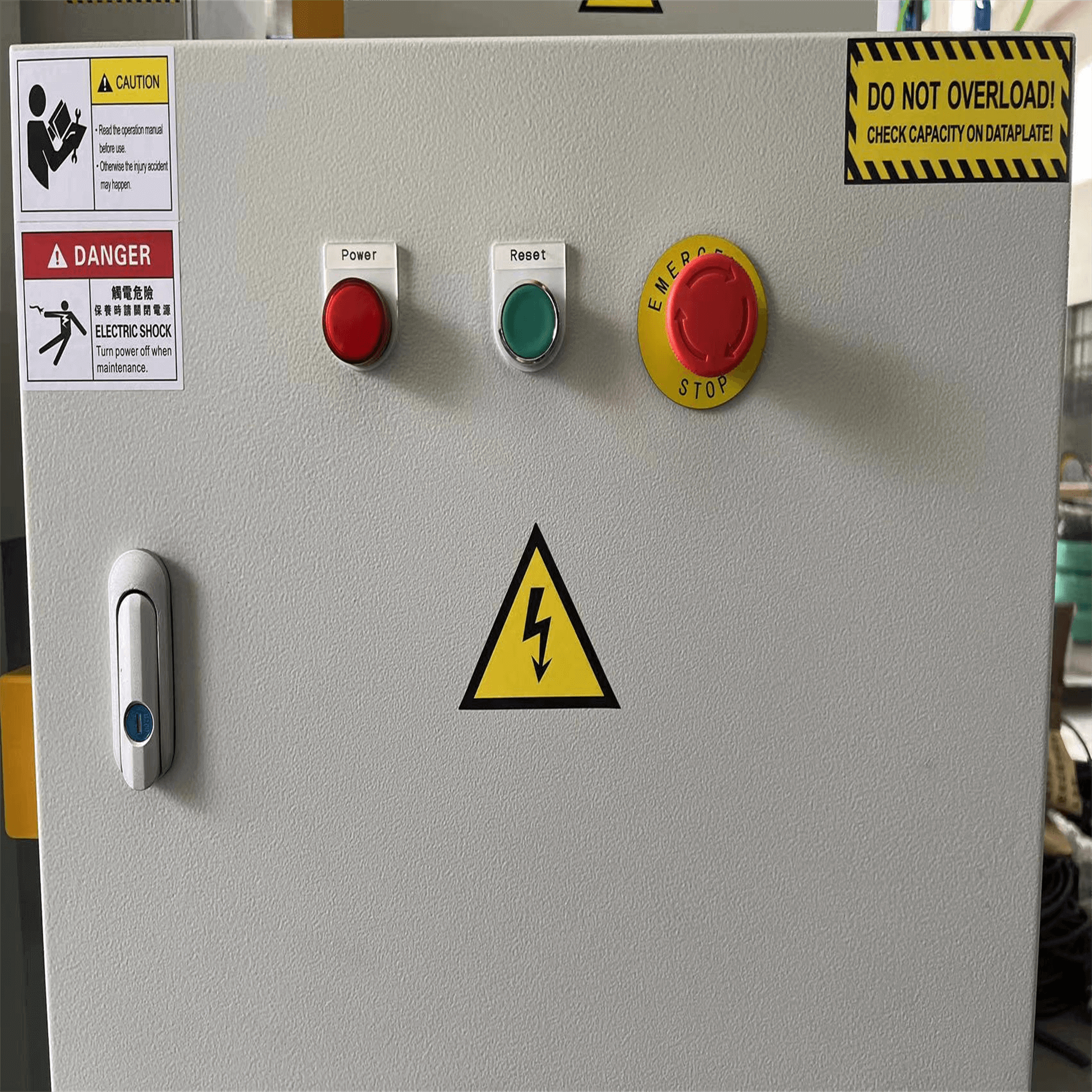

- Control System: The positioner may have a control system that allows operators to adjust the hydraulic lifting, rotation speed, and other parameters. This provides precise control over the welding process.

Hydraulic lifting pipe turning welding positioners are commonly used in industries such as oil and gas, pipeline construction, and fabrication. They are specifically designed for welding large-diameter pipes or cylindrical workpieces, such as pipelines, pressure vessels, and storage tanks.

These positioners improve the efficiency and safety of welding operations by providing stable support, controlled rotation, and easy access to all sides of the workpiece. The hydraulic lifting mechanism enables precise positioning and height adjustment, while the rotation capability allows welders to achieve consistent and high-quality welds.

✧ Main Specification

| Model | EHVPE-20 |

| Turning Capacity | 2000kg maximum |

| Table diameter | 1000 mm |

| Lifting way | Hydraulic cylinder |

| Lifting cylinder | One cylinders |

| Lifting center stroke | 600~1470 mm |

| Rotation way | Motorized 1.5 KW |

| Tilt way | Hydraulic cylinde |

| Tilting cylinder | One cylinders |

| Tilting angle | 0~90° |

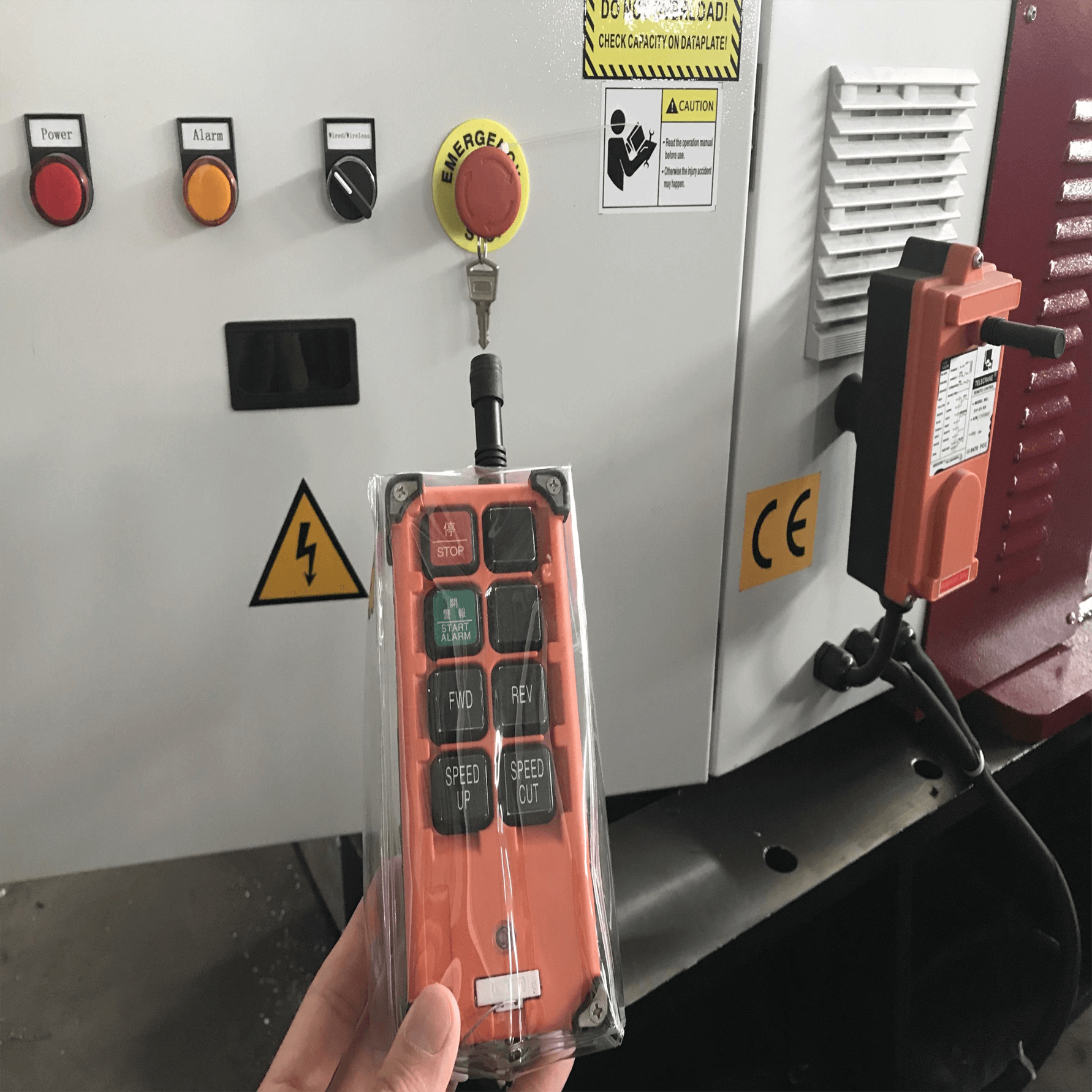

| Control way | Remote hand control |

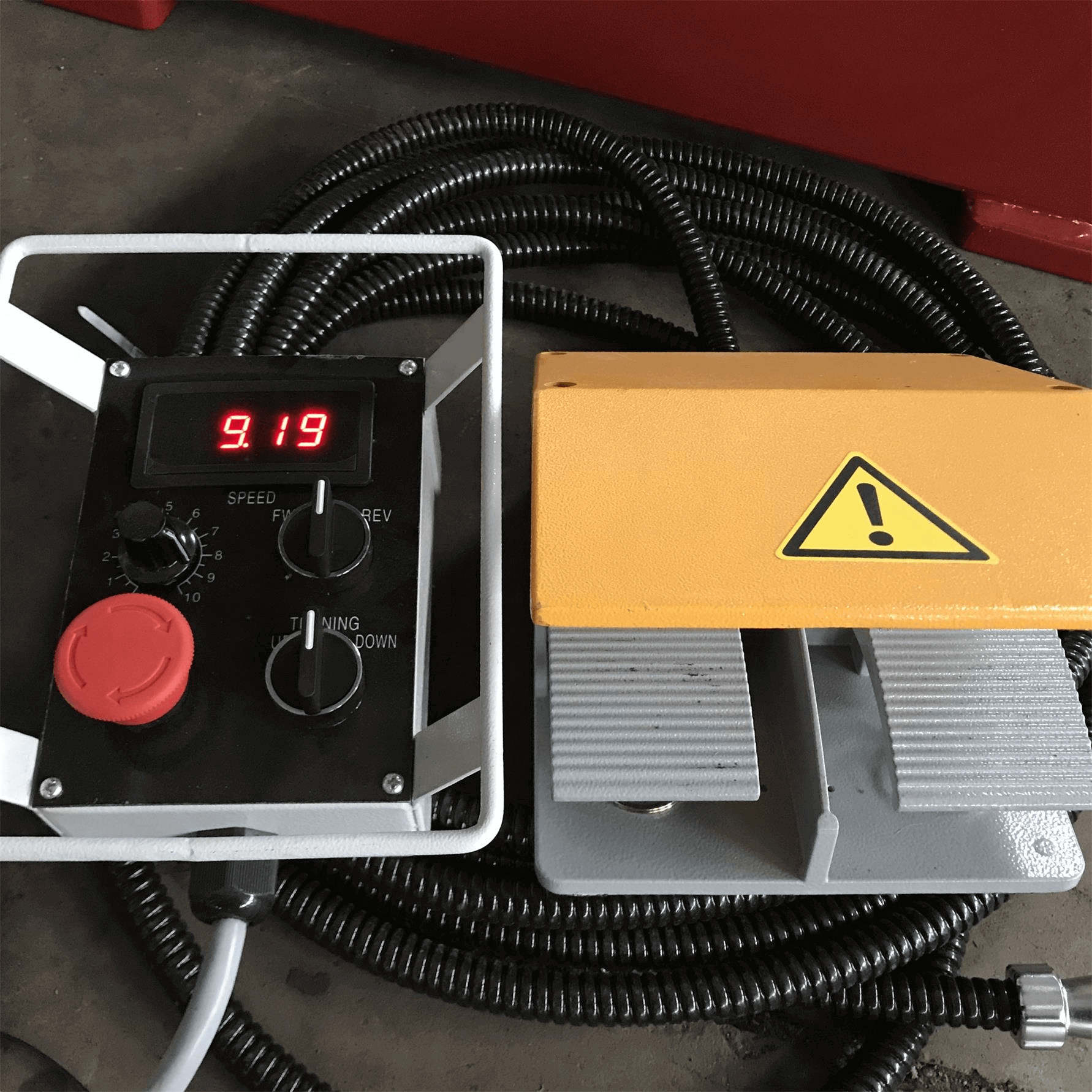

| Foot switch | Yes |

| Voltage | 380V±10% 50Hz 3Phase |

| Control system | Remote control 8m cable |

| Color | Customized |

| Warranty | One year |

| Options | Welding chuck |

✧ Spare Parts Brand

For international business, Weldsuccess use all the famous spare parts brand to ensure the welding rotators with long time using life. Even the spare parts broken after years later, the end user also can replace the spare parts easily at the local market.

1.Frequency changer is from Damfoss brand.

2.Motor is from Invertek or ABB brand.

3.Electric elements is Schneider brand.

✧ Control System

1.Normally the welding positioner with hand control box and foot switch.

2.One hand box, the worker can control Rotation Forward, Rotation Reverse, Emergency Stop functions, and also have the rotation speed display and power lights.

3.All the welding positioner electric cabinet made by Weldsuccess Ltd itself. The main electric elements are all from Schneider.

4.Sometimes we did the welding positioner with PLC control and RV gearboxes, which can be work together with robot as well.

✧ Production Progress

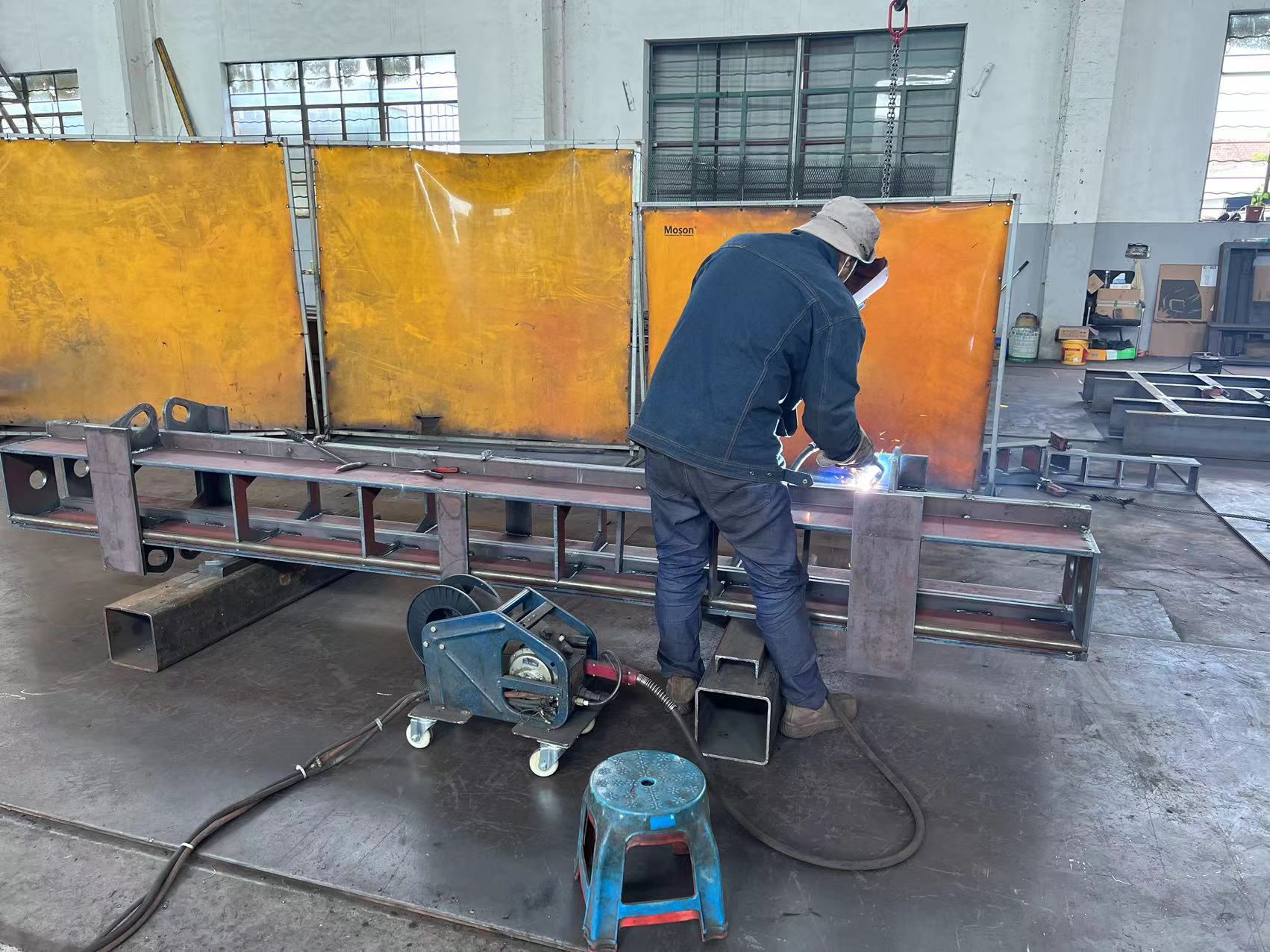

WELDSUCCESS as a manufacturer, we produce the welding rotators from the original steel plates cutting, welding, mechanical treatment, drill holes, assembly, painting and final testing.

In this way, we will control all the production process is under our ISO 9001:2015 quality management system. And ensure our customer will receive a high quality products.

✧ Previous Projects