Automation LHC 2020 Welding Column And Boom Manipulator For Pressure Vessels

✧ Introduction

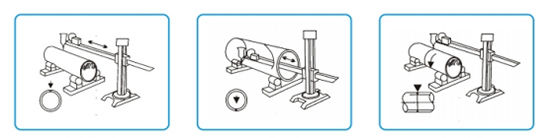

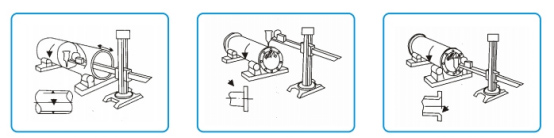

1.Welding column boom are widely used for wind tower, pressure vessels and tanks outside and inside longitudinal seam welding or girth welding. It will be realize the automatic welding when using together with our welding rotators system.

2.Using together with welding positioners will be more convenient to welding the flanges as well.

3.According to the work pieces length, we also make the column boom with traveling wheels basis. So it also available for welding long longitudinal seam welding.

4.On the welding column boom, we can install the MIG power source, SAW power source and AC/DC tandem power source as well.

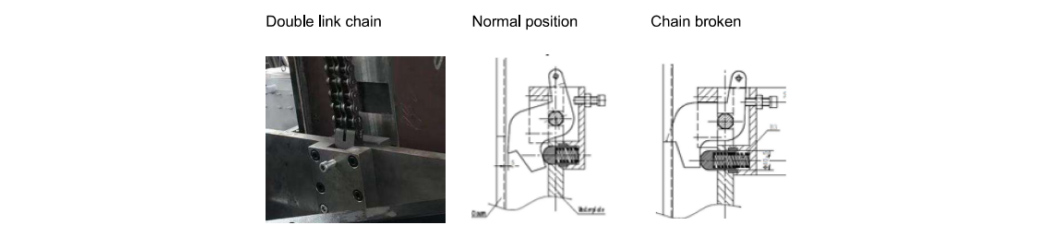

5.The welding column boom system is lifting by double link chain. It also with anti-falling system to ensure the using safety even the chain broken.

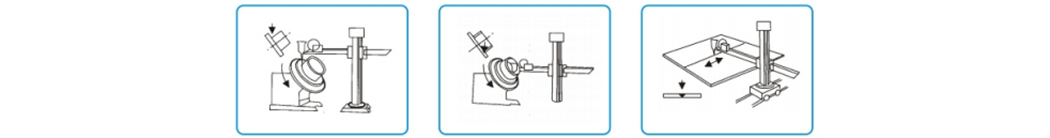

6.Flux recovery machine, welding camera monitor and laser pointer are all available to realize the automatic welding. You can email us for the working video.

✧ Main Specification

| Model | MD 2020 C&B |

| Boom end load capacity | 250kg |

| Vertical boom travel | 2000 mm |

| Vertical boom speed | 1000 mm/min |

| Horizontal boom travel | 2000 mm |

| Horizontal boon speed | 120-1200 mm/min VFD |

| Boom end cross slide | Motorized 100*100 mm |

| Rotation | ±180°Manual with lock |

| Traveling way | Motorized traveling |

| Traveling speed | 2000 mm/min |

| Voltage | 380V±10% 50Hz 3Phase |

| Control system | Remote control10m cable |

| Color | Customized |

| Warranty | 1 Year |

| Options-1 | Laser pointer |

| Options -2 | Camera monitor |

| Options-3 | Flux recovery machine |

✧ Spare Parts Brand

For international business, Weldsuccess use all the famous spare parts brand to ensure the welding column boom with long time using life. Even the spare parts broken after years later, the end user also can replace the spare parts easily at the local market.

1.Frequency changer is from Damfoss brand.

2.Motor is from Invertek or ABB brand.

3.Electric elements is Schneider brand.

✧ Control System

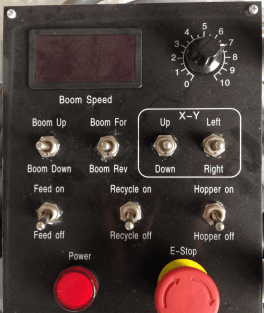

1.Hand control box with boom up / boom down, boom forward / backwards / Cross slides to adjust the welding torch up down left right, Wire feeding, Wire back, Power Lights and E-stop.

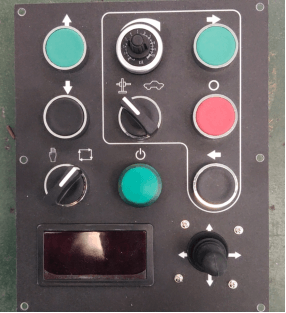

2.Main electric cabinet with power switch,Power Lights, Alarm , Reset functions and Emergency Stop functions.

3.We also can integrate the welding rotator or welding positioner with the column boom to realize the automatic welding.

✧ Previous Projects

WELDSUCCESS as a manufacturer, we produce the welding column boom from the original steel plates cutting, welding, mechanical treatment, drill holes, assembly, painting and final testing.

In this way, we will control all the production process is under our ISO 9001:2015 quality management system. And ensure our customer will receive a high quality products.