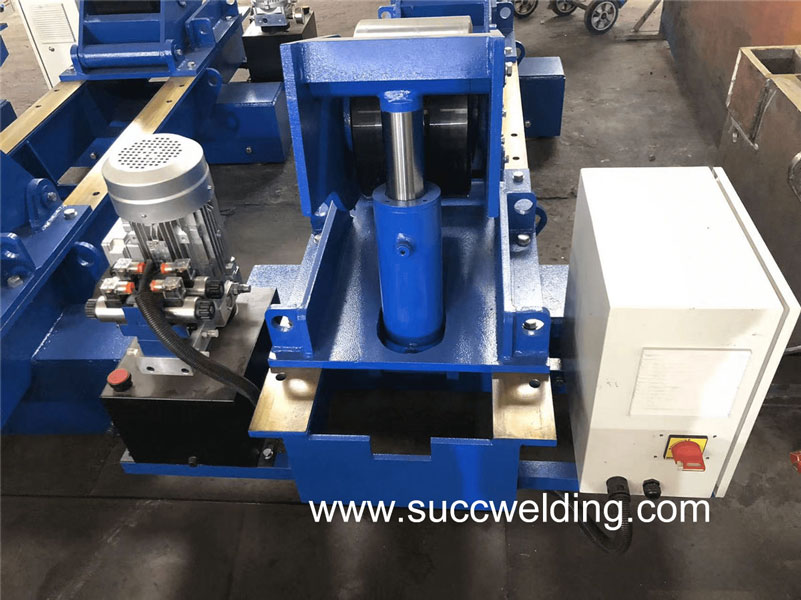

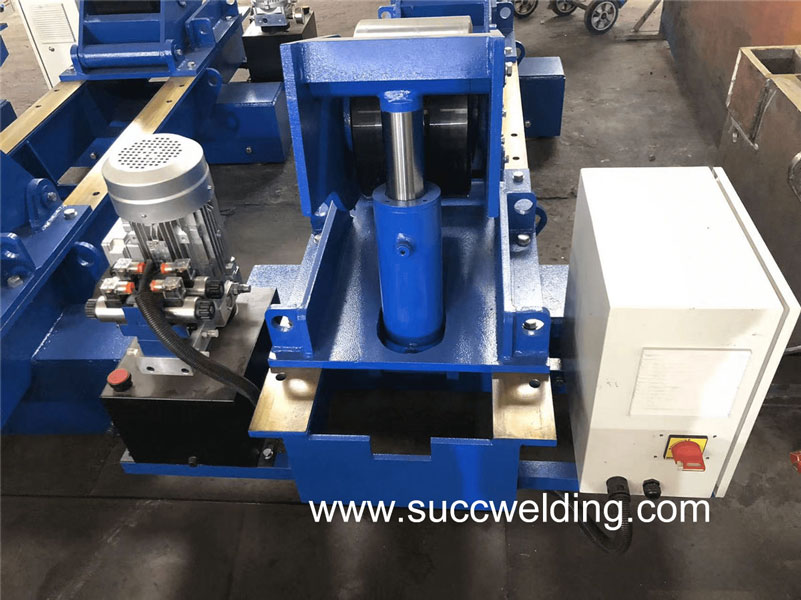

Hydraulic 40 T Fit Up Welding Rotator For Wind Towers

✧ Introduction

1. Hydraulic welding rotators adjust by oil cylinder for serveral single pipes welding together.

2. Fit up welding rotator with jacking system up / down by wireless hand control during butt welding.

3. Horizontal adjust fit up welding rotators also available for butt welding.

4. Fit up welding rotators with hydraulic jacking system but only idler turning.

5. Using together with self aligning welding rotator or conventional welding rotators together.

6. Hydraulic welding rotator with jacking system,fit up welding rotators with wireless hand control.

✧ Main Specification

| Model | FT-40 Welding Roller |

| Load Capacity | 20 ton maximum*2 |

| Adjust Way | Bolt adjustment |

| Hydraulic adjust | Up/Down |

| Vessel Diameter | 500~4500mm |

| Motor Power | 2*1.5kw |

| Traveling way | Manual traveling with lock |

| Roller wheels | PU |

| Roller size | Ø400*200mm |

| Voltage | 380V±10% 50Hz 3Phase |

| Control system | Wireless hand box |

| Color | Customized |

| Warranty | One year |

| Certification | CE |

✧ Feature

1.Both sections have a free multi-dimensional adjustment capability.

2.The adjustment work is more flexible and can better accommodate different types of welding seam status.

3.The hydraulic V-wheel facilitates the axial movement of the tower.

4.It could greatly improve the working efficiency for thin wall thickness and large pipe diameter production.

5.Hydraulic Fit Up Rotator consists of a 3D adjustable shift rotator, a hydraulic working station with effective control.

6.Rotator base is made of welded plate, with a higher strength to ensure no curvature occurs over a period of time.

7.Rotator base & boring is an embedded process to ensure precise rotation of the roller.

✧ Spare Parts Brand

1.Variable Frequency Drive is from Danfoss / Schneider brand.

2.Rotation and tilring Motors are Invertek / ABB brand.

3.Electric elements is Schneider brand.

All the spare parts are easily to replace at end user local market.

✧ Control System

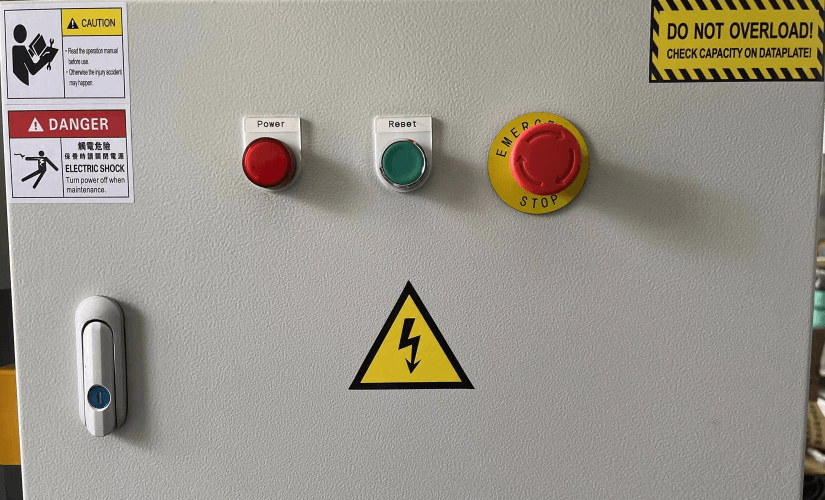

1.Remote Hand control box with Rotation speed display, Rotation Forward , Rotation Reverse, Tilting Up, Tilting Down, Power Lights and Emergency Stop functions.

2. Main electric cabinet with power switch,Power Lights, Alarm , Reset functions and Emergency Stop functions.

3.Foot pedal to control the rotation direction.

4.We also add one additional Emergency stop button on the machine body side, this will ensure the work can stop the machine at the first time once any accident occur.

5.All our control system with CE approval to European market.

✧ Previous Projects