FT-20 Hydraulic Fit Up Welding Rotator for Pipe Butt Welding

✧ Introduction

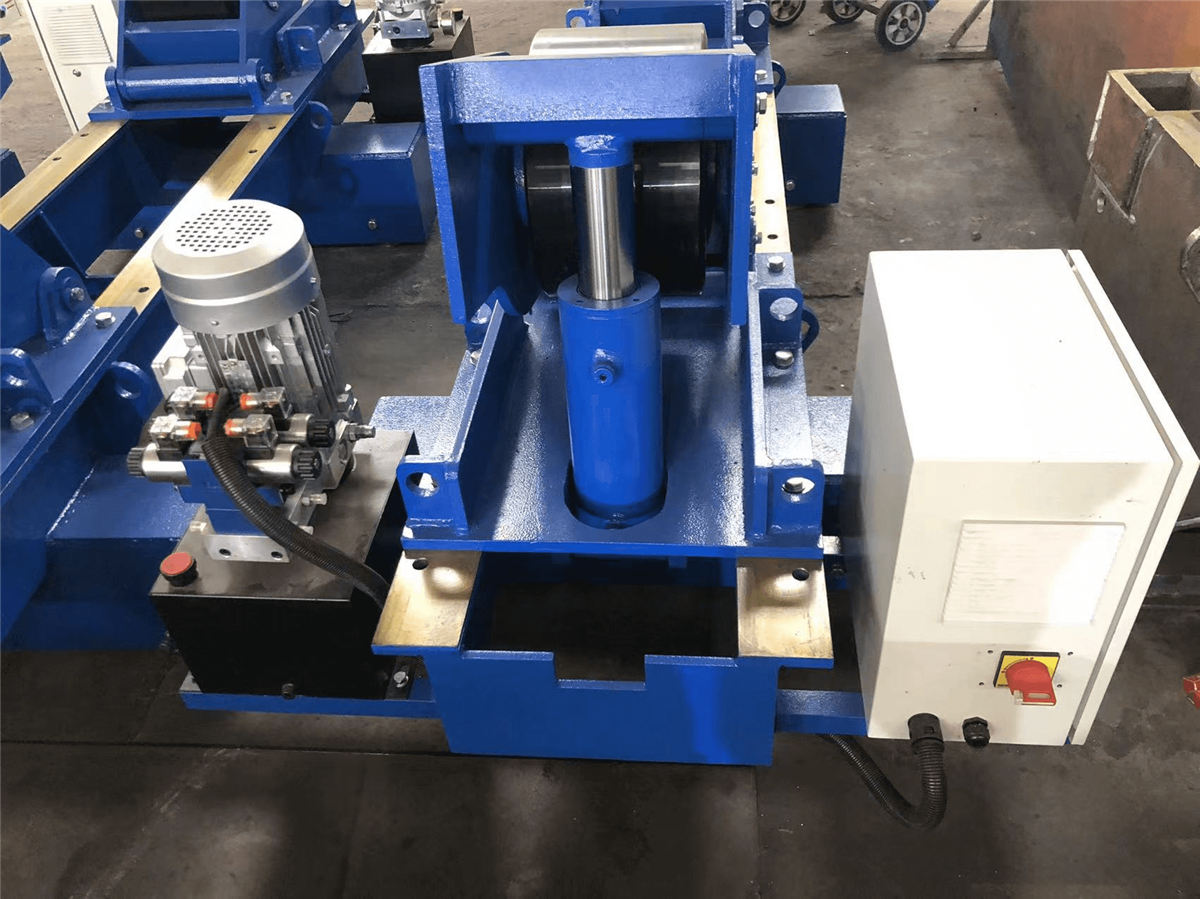

Hydraulic fit up welding rotator consists of two idler free turning unit with hydraulic cylinders and whole electric control system. According to the pipe length, customer also can choose fixed basis or motorized traveling basis.

Hydraulic fit up welding rotator can adjust the vessels up or down during two vessels butt welding. It will give much help to improve the automatic welding.

Hydraulic fit up welding rotator with one wireless hand control box. Workers can adjust the vessels position in 30m ranges.

1.Conventional welding rotator consists of one drive rotator unit with motor, one idler free turning unit and whole electric control system. According to the pipe length, customer also can choose one drive with two idlers.

2.The Drive rotator turning with 2 Inverter Duty A.C Motors and 2 Gear Transmission Reducers and 2 PU or Rubber material wheels and Steel Plate Basis.

✧ Main Specification

| Model | FT- 20 Welding Roller |

| Turning Capacity | Idler support |

| Loading Capacity | 20 tons maximum (10 tons each) |

| Vessel size | 500~3500mm |

| Adjust Way | Hydraulic up / down |

| Rotation motor | Idler support |

| Roller wheels | Steel coated with PU type |

| Control system | Remote hand control box |

| Color | RAL3003 RED & 9005 BLACK / Customized |

| Options | Large diameter capacity |

| Motorized traveling wheels basis | |

| Wireless hand control box |

✧ Spare Parts Brand

For international business, Weldsuccess use all the famous spare parts brand to ensure the welding rotators with long time using life. Even the spare parts broken after years later, the end user also can replace the spare parts easily at the local market.

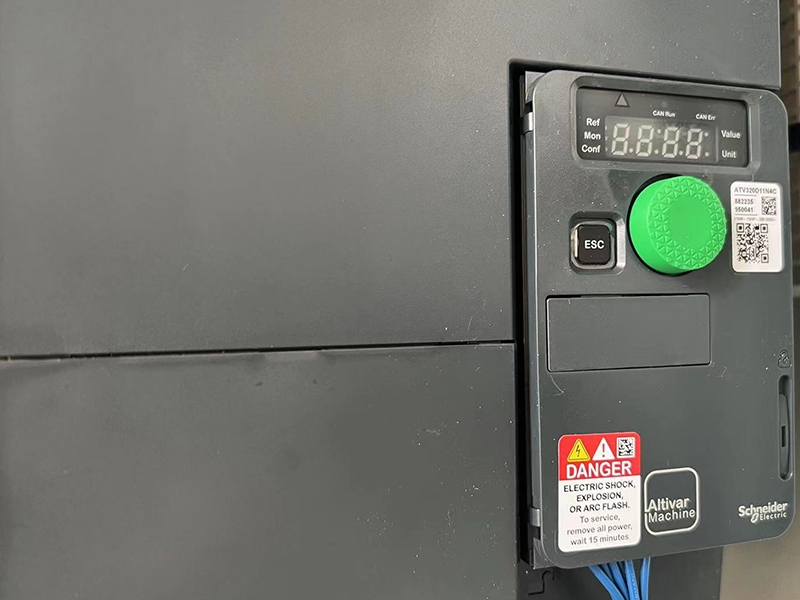

1.Frequency changer is from Damfoss brand.

2.Motor is from Invertek or ABB brand.

3.Electric elements is Schneider brand.

✧ Control System

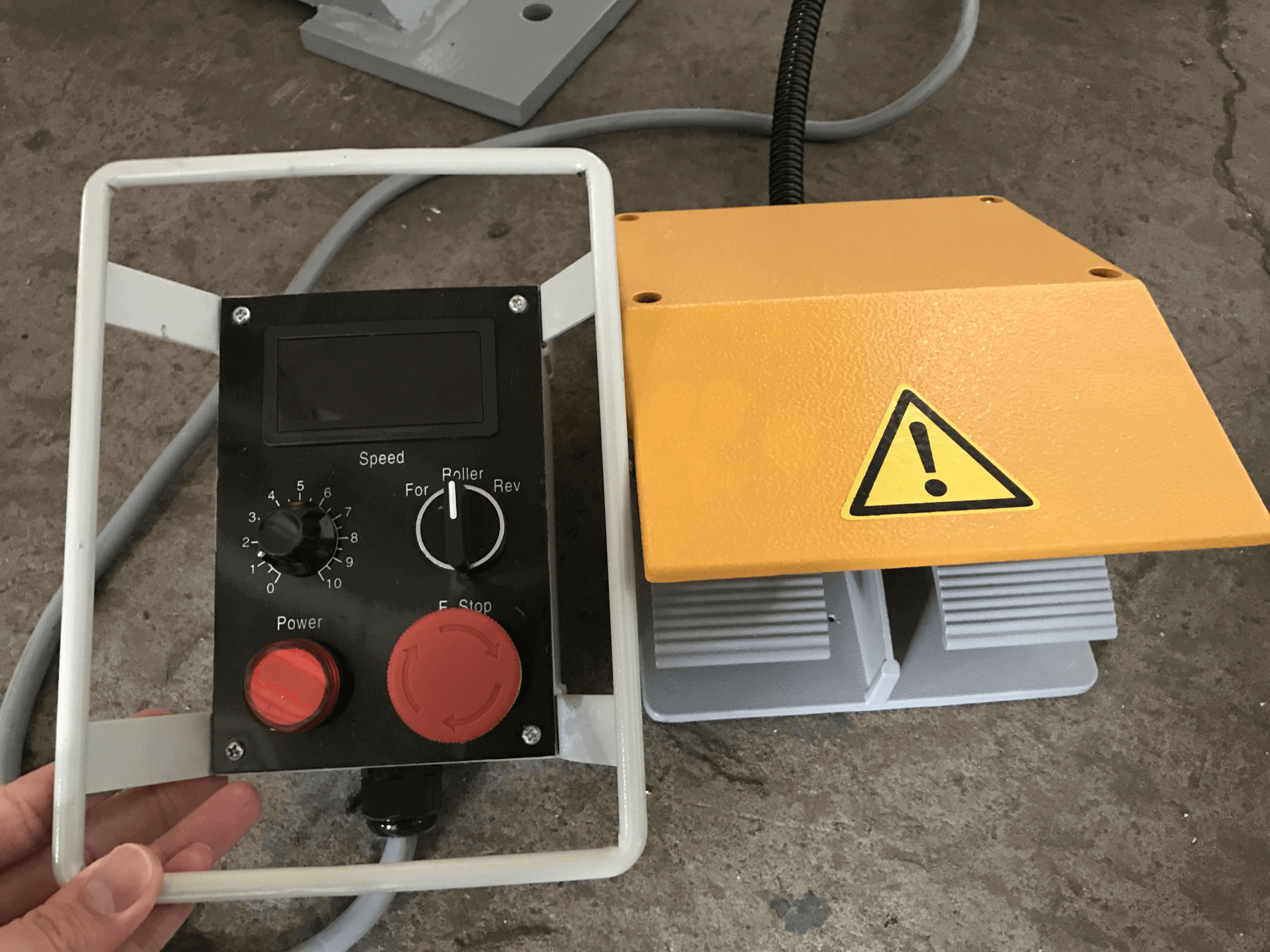

1.Hand control box with Rotation speed display, Forward , Reverse, Power Lights and Emergency Stop functions.

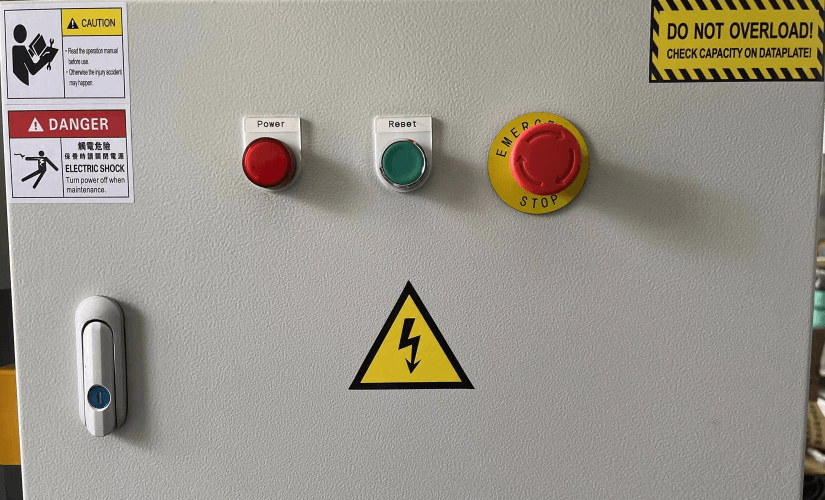

2.Main electric cabinet with power switch,Power Lights, Alarm , Reset functions and Emergency Stop functions.

3.Foot pedal to control the rotation direction.

4.Wireless hand control box is available if needed.

✧ Production Progress

WELDSUCCESS as a manufacturer, we produce the welding rotators from the original steel plates cutting, welding, mechanical treatment, drill holes, assembly, painting and final testing.

In this way, we will control all the production process is under our ISO 9001:2015 quality management system. And ensure our customer will receive a high quality products.

✧ Previous Projects